Million dollar project transforms CO2 into green material

The prestigious North-C-Methanol project reduces CO2 emissions by 140,000 tonnes annually and produces 44,000 tonnes of green methanol.

In North Sea Port, 10 private and public partners gave the start for the North-C-Methanol project. The aim of the project? Together reducing CO2 emissions by 140,000 tonnes annually and producing 44,000 tonnes of green methanol for the local chemical and renewable energy industries and as fuel for ships and trains. This world-class project includes the largest renewable hydrogen-to-methanol construction in the world.

Demo plant with green production process

North-C-Methanol is the first large-scale demo plant under the North-CCU-Hub programme, representing an investment of € 140 million. The North-CCU-Hub programme aims to eventually achieve a total annual emission reduction of 1 million tonnes of CO2 in North Sea Port. On 21 October 2020, 10 private and public partners signed the formal cooperation agreement for the North-C Methanol project. This proves the need for a more sustainable future. The private partners, together with PMV, will bear a large part of the investments, and Flemish and European support is also being sought.

Largest installations of their kind

North-C-Methanol foresees the construction of two large-scale demo plants and supporting infrastructure on the Rodenhuize peninsula at North Sea Port.

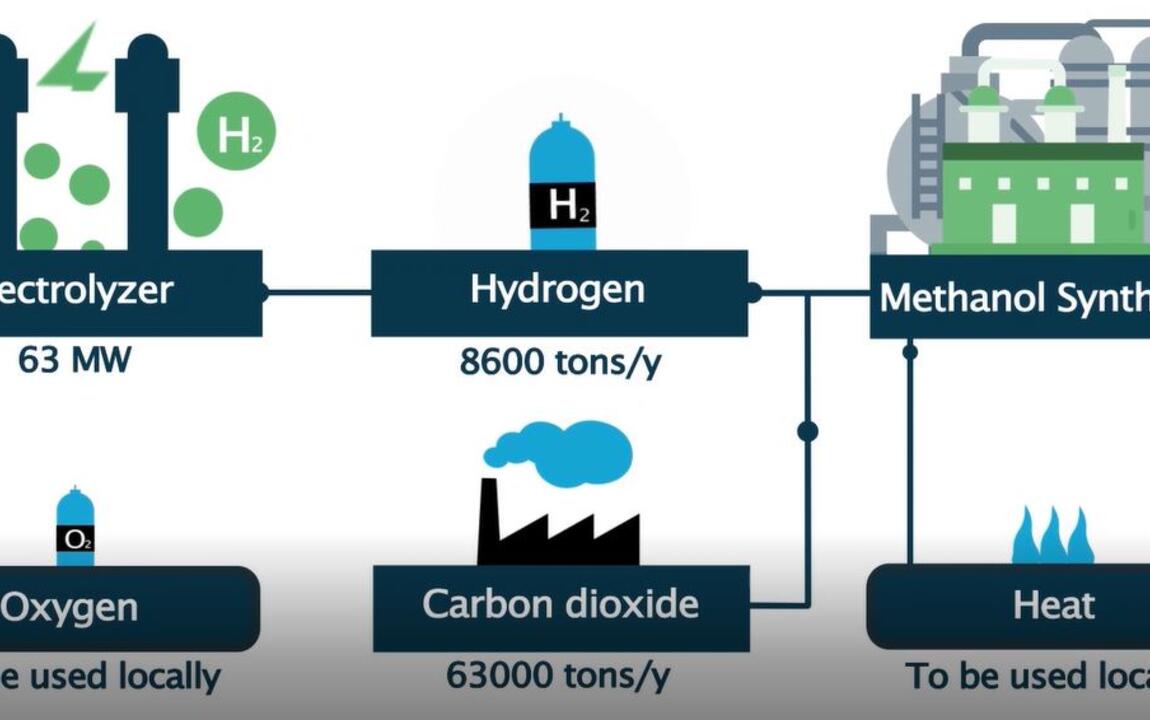

- The first plant, a 65 megawatt electrolyser, will be built on the ENGIE site. This hydrogen plant will convert water into green hydrogen and oxygen via wind energy. Cedric Osterrieth, director of ENGIE's thermal operations in Europe, calls it a logical choice: "We already have a direct high-voltage grid connection with renewable energy, sourced from wind in the North Sea. We can use that energy to produce hydrogen, which in turn can serve as a sustainable raw material."

- The second plant, a methanol plant run by Proman on the Rodenhuize peninsula, will use this green hydrogen to convert the captured CO2 emissions from major local industrial players such as ArcelorMittal, Alco Bio Fuel and Yara into green methanol. The local chemical and renewable fuel industry, to which Cargill belongs, will in turn buy the methanol as green feedstock and/or as green fuel for ships and trains. David Cassidy, CEO of Proman: "We are excited to further develop the potential of methanol as a clean fuel for the future. Green methanol offers a significant opportunity to bridge the gap from fossil to renewable energy."

Circular showpiece

North-C-Methanol is a fine example of sustainable industrial symbiosis: the raw materials are extracted locally and the end products and by-products are used locally. In North Sea Port, a new circular economy is created: waste from one company becomes raw material for another company. All by-products of methanol production, such as oxygen, heat and water, are also reused locally. This creates a unique and far-reaching industrial and circular integration. Of course, all this goes hand in hand with the construction of a lot of supporting infrastructure such as new pipelines and storage tanks to bring raw materials, by-products and end products to the right location. Fluxys and Oiltanking will be responsible for this. Mitsubishi Power will take care of the integration and coordination of the entire construction process.

"This project shows why we in Flanders can become a leader in sustainable innovation. With our ports and their industry, we are ideally positioned to invest in a circular and sustainable industry. It ensures sustainable growth and new jobs, and with this type of project we are making a leap forward towards a resilient Flanders. Moreover, it is also a step towards becoming less dependent on fossil raw materials from abroad," says Flemish Vice Minister Hilde Crevits.

Local and green economy

The Ghent part of North Sea Port is the perfect location. There are a lot of industrial CO2 emissions that can be captured, a high-voltage connection and many potential customers for green methanol. "With this cooperation, we strengthen our position in the field of the circular economy that we already have in the port," says CEO Daan Schalck of North Sea Port. "The port also has extensive logistics activities, a huge storage capacity and connections by sea, barge, rail and road." In addition, within the North-CCU-Hub you will find a strong knowledge cluster around chemical (bio)technology. The City of Ghent and the Province of East Flanders are helping to facilitate the project. PMV is helping with the financial part.

Impact on a global scale

Apart from the far-reaching integration of the different processes and between various industrial partners, the North-C Methanol project is also unique because of its scale and its medium- and long-term innovation programme. The electrolysis capacity will be no less than 6 times larger than the largest system currently operating worldwide.

North-CCU-Hub foresees a gradual upscaling of the North-C methanol capacity from 65 MW in 2024 to 600 MW in 2030. And also in an innovation programme where new technologies, markets and products such as ammonia, formic acid, fatty acids, esters and proteins will gradually be developed and integrated. Knowledge partners UGent, Bio Base Europe Pilot Plant, CAPTURE and the Flemish spearhead clusters Catalisti and Flux50 give shape to these innovation trajectories.

North-C-Methanol project

Read all about the North-C-Methanol project and the North-CCU-Hub.

Read more